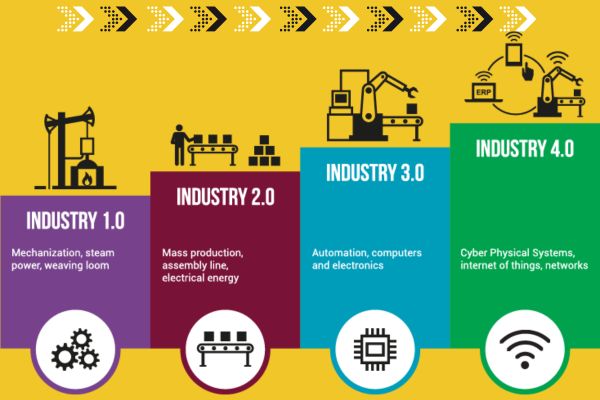

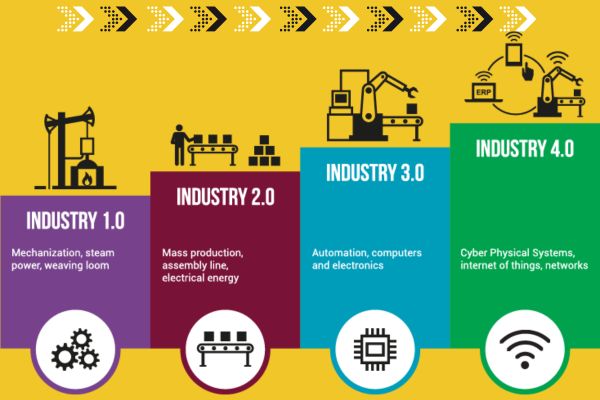

Industry 4.0

The Fourth Industrial Revolution is characterized by the convergence of smart machines, autonomous robots, edge computing and big data.

We as enterprises are being driven by a divergent applications, which are so crucial to business of the organization. Quality and Stability of the application is major concerns for every team. Performaing Manual Testing for ensuring the quality and stability of such application is time-consuming and is not accurate. Implementing the automation testing reduces the time and cost and improves the quality of application for every releases.Robotic process automation (RPA) is an emerging form of business process automation technology based on the artificial intelligence. It Reduces the testing time by 60% and saves time and cost. Once set up to follow regulations and standards, bots will never deviate from the assigned execution path.

In the first phase, dedicated to equipment connectivity implementation, devices, machines, production lines, and factories establish connections with the system, ushering in a new era of data transparency and information visualization. Subsequently, the second phase introduces data collection, integration, and the integration of value-added products and services, laying the foundation for smart manufacturing services. The third and final phase focuses on intelligent innovative services, enabling the deployment of intelligent machinery and comprehensive big data analysis. Advantech plays a pivotal role in driving these advancements, facilitating the development of network-connected iFactories and iMachinery, thereby catalyzing the evolution toward smart manufacturing. Moreover, six distinct smart factory solutions have been identified, including Machine Automation, Equipment Monitoring & Optimization, Machine Monitoring & Predictive Maintenance, MES Integration & Production Traceability, Factory Energy Management System, and Factory Environment Monitoring. These solutions are meticulously crafted through integrated automation and cloud innovation tailored specifically for Industry 4.0.

One critical facet of this transformative journey is Machine Automation, leveraging the integration of machine vision and motion. This integration empowers Robotics and Automated Guide Vehicles (AGVs) to diminish dependence on manpower, ushering in lean production and the potential for unmanned production. The system encompasses various elements, including the automation of board/system testing operations, the integration of a translation robot arm in chassis factories, and the application of IC Automatic feeders (electric, pneumatic, hydraulic). Additionally, a field operations interactive platform (ESD, ESOP) contributes to enhancing overall operational efficiency.